........... EXECUTIVE SUMMARY

2.......... Project Information

2.3 Construction Programme and Activities

2.5 Status of Environmental Licences, Notification and

Permits

3.......... Environmental

Monitoring Requirements

3.1 Construction Dust Monitoring

3.2 Construction Noise Monitoring

4.......... Implementation Status of Environmental

Mitigation Measures

5.......... Monitoring Results

5.1 Construction Dust Monitoring

5.2 Regular Construction Noise Monitoring

6.......... ENVIRONMENTAL SITE INSPECTION AND AUDIT

7.......... Environmental

Non-conformance

7.1 Summary of Monitoring Exceedances

7.2 Summary of Environmental Non-Compliance

7.3 Summary of Environmental Complaints

7.4 Summary of Environmental Summon and Successful

Prosecutions

8.1 Construction Programme for the Next Three Months

8.2 Key Issues for the Coming Month

8.3 Monitoring Schedule for the Coming Month

9.......... ConclusionS AND RECOMMENDATIONS

List of Tables

Table 2.1.......... Construction Activities in the reporting month

Table 2.2.......... Contact Information of Key

Personnel

Table 2.3.......... Status of Environmental

Licenses, Notifications and Permits

Table 3.1

........ Air

Quality Monitoring Equipment

Table 3.2

........ Location

of Construction Dust Monitoring Station

Table 3.3 ........ Noise Monitoring

Parameters, Frequency and Duration

Table 3.4

........ Noise

Monitoring Equipment for Regular Noise Monitoring

Table 3.5 ........ Noise Monitoring Stations

during Construction Phase

Table 3.6 ........ Noise Monitoring

Parameters, Frequency and Duration

Table 4.1.......... Status of Required Submission under Environmental

Permit

Table 5.1 ........ Summary of 24-hour TSP

Monitoring Result in the Reporting Period

Table 5.2 ........ Summary of 1-hour TSP

Monitoring Result in the Reporting Period

Table 5.3 ........ Summary of Construction

Noise Monitoring Results in the Reporting Period

Table 6.1 ........ Observations and

Recommendations of Site Audit

Table 8.1.......... Construction Activities in the coming three months

List of Figures

|

Site Layout Plan |

|

|

Location of Air Quality Monitoring Station |

|

|

Locations of Noise Monitoring Station |

|

|

|

|

List

of Appendices

|

Construction Programme |

|

|

Project Organization Structure |

|

|

Implementation Schedule of Environmental Mitigation Measures |

|

|

Summary of Action and Limit Levels |

|

|

Calibration Certificates of Equipment |

|

|

EM&A Monitoring Schedules |

|

|

Air Quality Monitoring Results and their Graphical Presentations |

|

|

Noise Monitoring Results and their Graphical Presentations |

|

|

Event and Action Plan Cumulative Statistics on Complaints, Notification of Summons and Successful

Prosecutions |

|

|

Monthly Summary Waste Flow Table Shatin to Central Link (Hung Hom – Admiralty

Section) Kai Tak Barging Facility under FEP-01/436/2012/F Monthly EM&A

Report |

|

|

|

|

EXECUTIVE SUMMARY

Central Kowloon Route – Kai Tak West (CKR-KTW; Contract No.

HY/2014/07) (hereafter called “the Project”) covers part of the construction of

the Central Kowloon Route (CKR).

The Project comprises

the follow works:

·

50x30m

access shaft with noise enclosure at Ma Tau Kok

(MTK);

·

100m long

cut-and-cover (C&C) tunnel at MTK;

·

Demolition

and re-provisioning of MTK Public Pier;

·

160m long

underwater tunnel (UWT) (Stage 1);

·

210m long

UWT (Stage 2);

·

60m long

C&C tunnel at Kai Tak;

·

130m long

depressed road and 200m long underpass at Kai Tak;

·

390m long

underground tunnel ventilation audit at Kai Tak;

·

Seawall

demolition and construction of new landing steps; and

·

Barging

Point enclosure and conveyor system.

The EM&A programme commenced on 4 April 2018.The impact EM&A for the Project includes air

quality and noise monitoring.

This is the 58th

monthly EM&A Report presenting the EM&A works carried out during the

period between 1 and 31 January 2023. As informed by the Contractor, major

activities in the reporting period were:

|

Locations |

Site Activities |

|

Kai Tak |

- Road pavement at underpass,

depressed road and C&C; - Precast profile barrier

installation at underpass, depressed road and C&C Tunnel; - Base slab, tunnel wall and

walkway construction at At-grade Road; - Stitch joint construction at

underpass, depressed road and C&C Tunnel. |

|

Ma Tau Kok |

- Temporary traffic management

(TTM) implementation; - Excavation at MTK C&C

Tunnel; - Decking and Excavation and

Lateral Support (ELS) installation at MTK C&C Tunnel; - Pumping Test at MTK C&C Tunnel. |

|

Kowloon Bay |

- Road pavement at Stage 1 UWT; - Temporary Reclamation at

Stage 2 UWT; - Modular strutting

installation at Stage 2 UWT; - Dredging/ Excavation of

marine sediment at Stage 2 UWT; - Pumping Test at Stage 2 UWT |

Breaches of Action and Limit Levels for Air Quality

All 24-hour TSP result was below the Action and Limit Levels at all

monitoring locations in the reporting month.

All 1-hour TSP result was below the Action and Limit Levels at all

monitoring locations in the reporting month.

Breaches of Action and Limit Levels for Noise

Regular Noise Monitoring

One (1) action level exceedance was recorded regarding to complaint on

noise nuisance received in the reporting month. No limit level exceedance was

recorded at all monitoring stations in the reporting month.

Complaint, Notification of Summons and Successful Prosecution

Five (5) complaints

were received in the reporting month (January 2023) and the investigation was

provided in the current reporting month (January 2023).

Reporting Changes

No report changes in the reporting period.

Future Key Issues

Key issues to be

considered in the next three months included:

|

Locations |

Site Activities |

|

Kai Tak |

- Road Pavement at underpass,

depressed road and C&C; - Stitch joint construction at

underpass, depressed road and C&C Tunnel; - Tunnel wall and walkway

construction at At-grade road. |

|

Ma Tau Kok |

- TTM implementation; - Excavation at MTK C&C

Tunnel; - Decking and ELS installation

at MTK C&C Tunnel; |

|

Kowloon Bay |

- Road pavement at Stage 1 UWT; - Modular strutting

installation at Stage 2 UWT - Excavation at Stage 2 UWT. |

Potential environmental

impacts arising from the above construction activities are mainly associated with construction dust, construction noise, water pollution control, and

waste management.

1

INTRODUCTION

Gammon Construction Limited was

commissioned by the Highways Department as the Civil Contractor for Works

Contract HY/2014/07. AECOM Asia Company Limited (AECOM) was appointed by Gammon

Construction Limited as the Environmental Team (ET) to undertake the

Environmental Monitoring and Audit (EM&A) programme

during construction phase of the Project.

1.1 Purpose of the Report

1.1.1

This is the 58th monthly EM&A Report which summaries the impact

monitoring results and audit findings for the Project during the reporting

period between 1 and 31 January 2023.

1.2 Report Structure

1.2.1

This monthly

EM&A Report is organized as follows:

·

Section 1: Introduction

·

Section 2:

Project Information

·

Section 3:

Environmental Monitoring Requirement

·

Section 4:

Implementation Status of Environmental Mitigation Measures

·

Section 5:

Monitoring Results

·

Section 6:

Environmental Site Inspection and Audit

·

Section 7: Environmental Non-conformance

·

Section 8:

Future Key Issues

·

Section 9:

Conclusions and Recommendations

2

Project Information

2.1 Background

2.1.1

CKR is a dual

3-lane trunk road across central Kowloon linking the West Kowloon in the west

and the Kai Tak Development (KTD) in the east. The CKR will be about 4.7 km

long with an underground tunnel section of about 3.9 km long, in particular,

there will be an underwater tunnel of about 370 m long in Kowloon Bay to the

north of the To Kwa Wan Typhoon Shelter. It will connect the West Kowloon

Highway at Yau Ma Tei Interchange with the road

network at Kowloon Bay and the future Trunk Road T2 at KTD which will connect

to the future Tseung Kwan O – Lam Tin Tunnel (TKO-LTT) and Cross Bay Link

(CBL). CKR, Trunk Road T2 and TKO-LTT will form a strategic highway link,

namely Route 6, connecting West Kowloon and Tseung Kwan O. In addition, 3

ventilation buildings, which will be located in Ya Ma

Tei, Ho Man Tin and ex-Kai Tak airport area, are

proposed to ensure acceptable air quality within the tunnel.

2.1.2

The Environmental

Impact Assessment (EIA) Report for Central Kowloon Route (Register No.: AEIAR-171/2013)

was approved on 11 July 2013 under the Environmental Impact Assessment

Ordinance (EIAO). Following the approval of the EIA Report, an Environmental

Permit (EP) for CKR was granted on 9 August 2013 (EP No.: EP- 457/2013) for the

construction and operation. Variation of EP (VEP) was subsequently applied

and the latest EP (EP No. EP-457/2013/D) was issued by the Director of Environmental

Protection (DEP) on 15 June 2021. Further Environmental Permit (EP No.

FEP-01/457/2013/C) for CKR – Kai Tak West was issued on 28 February 2018.

2.1.3

The construction

of the CKR had been divided into different sections. This Work Contract

HY/2014/07 – Kai Tak West (KTW) (“The Project”) will include a road which is a

trunk road, including new roads, and major extensions or improvements to

existing roads; a road fully enclosed by decking above and by structure on the

sides for more than 100 m; and reclamation works (including associated dredging

works) more than 1 ha in size and a boundary of which is less than 100 m from

an existing residential area.

2.1.4

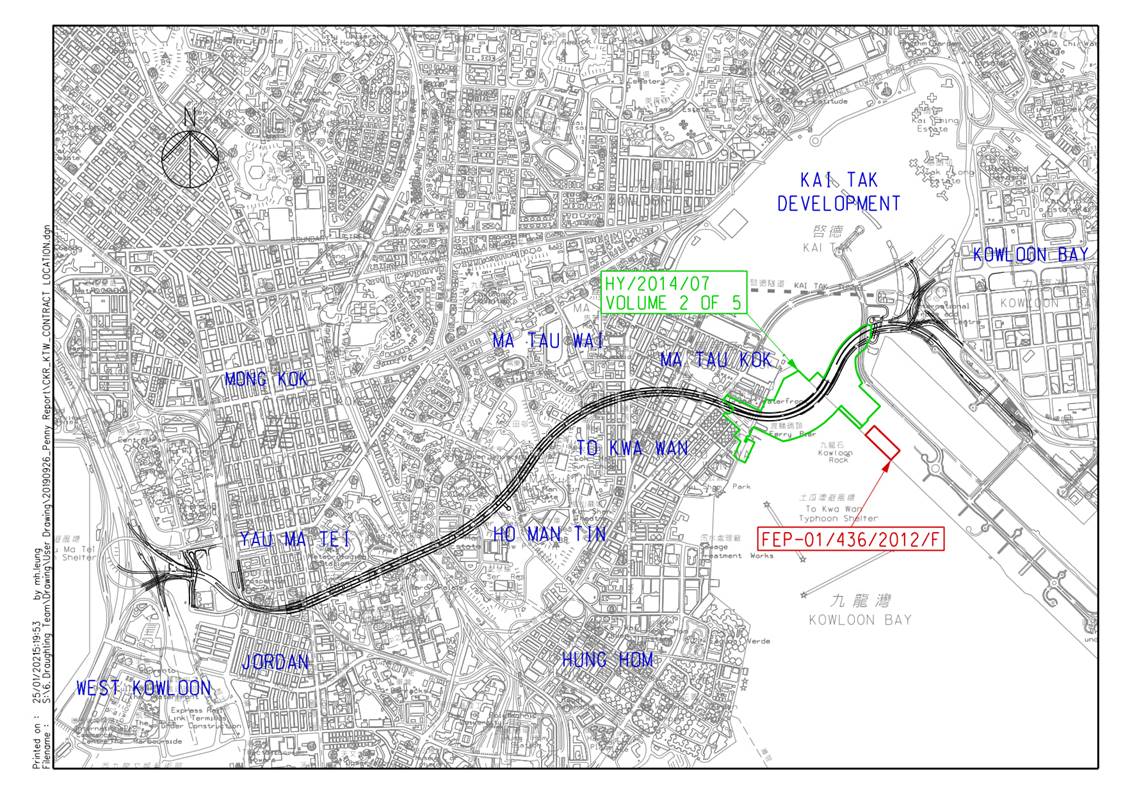

The site layout

plan of the Project is shown in Figure 1.1.

2.2 Site Description

2.2.1

The major

construction activities under this Project include:

(a)

construction of approximately 160m long

cut-and-cover tunnel and 370m long underwater tunnel between the tunnel section

at Ma Tau Kok and the depressed road of the CKR

within Kai Tak Development;

(b)

reconstruction of the seawall at Ma Tau

Kok public pier, and the sloping seawall at the

Former Kai Tak Airport Runway;

(c)

construction of approximately 125m long

depressed road and 200m long underpass of the CKR within Kai Tak Development;

(d)

construction of approximately 360m long

underground tunnel ventilation adit of the CKR;

(e)

reconstruction of Kowloon City Ferry

Pier Public Transport Interchange; and

(f)

other associated works.

2.3 Construction Programme and Activities

2.3.1

The major

construction activities undertaken in the reporting month are summarized in Table

2.1.

Table 2.1 Construction Activities in the reporting month

|

Locations |

Site Activities |

|

Kai

Tak |

-

Road pavement at underpass, depressed road and C&C; -

Precast profile barrier installation at underpass, depressed road and C&C

Tunnel; -

Base slab, tunnel wall and walkway construction at At-grade Road; -

Stitch joint construction at underpass, depressed road and C&C Tunnel. |

|

Ma

Tau Kok |

- Temporary

traffic management (TTM) implementation; -

Excavation at MTK C&C Tunnel; -

Decking and Excavation and Lateral Support (ELS) installation at MTK C&C

Tunnel; -

Pumping Test at MTK C&C Tunnel. |

|

Kowloon

Bay |

-

Road pavement at Stage 1 UWT; -

Temporary Reclamation at Stage 2 UWT; -

Modular strutting installation at Stage 2 UWT; -

Dredging/ Excavation of marine sediment at Stage 2 UWT; -

Pumping Test at Stage 2 UWT |

2.3.2

The construction programme is presented in Appendix

A.

2.4 Project Organization

2.4.1

The project

organization structure is shown in Appendix B. The key personnel contact names and

numbers for the Project are summarized in Table

2.2.

Table 2.2 Contact Information of Key Personnel

|

Party |

Role |

Position |

Name |

Telephone |

Fax |

|

Arup-Mott

MacDonald Joint Venture |

Residential

Engineer (ER) |

Engineer’s

Representative |

Mr. Patrick Lo |

36195901 |

2268 3954 |

|

ERM |

Independent

Environmental Checker (IEC) |

Independent

Environmental Checker |

Ms. Mandy To |

2271 3113 |

3015 8052 |

|

Gammon |

Contractor |

Contracts Manager |

Mr. Kin Fai Tam |

2516 8823 |

2516 6260 |

|

Environmental Manager |

Ms. Michelle Tang |

9267 8866 |

2516 6260 |

||

|

AECOM |

Contractor’s

Environmental Team (ET) |

ET Leader |

Mr. Y. W. Fung |

3922 9366 |

2317 7609 |

2.5 Status of Environmental Licences, Notification and Permits

2.5.1

Relevant environmental

licenses, permits and/or notifications on environmental protection for this

Project and valid in the reporting month are summarized in Table

2.3.

Table 2.3 Status of Environmental Licenses, Notifications and Permits

|

Permit / License No. / Notification/

Reference No. |

Valid Period |

Status |

Remarks |

|

|

|

From |

To |

|

|||

|

Further Environmental Permit |

|||||

|

FEP-01/457/2013/C |

28 Feb 2018 |

End of Project |

Valid |

-- |

|

|

Wastewater Discharge License |

|||||

|

WT00030290-2018 |

22 Mar 2018 |

31 May 2023 |

Valid |

Ma Tau Kok |

|

|

WT00030668-2018 |

27 Apr 2018 |

30 Apr 2023 |

Valid |

Site Office at Kai Tak West |

|

|

WT00030358-2018 |

27 Apr 2018 |

30 Apr 2023 |

Valid |

Kai Tak West |

|

|

WT00030330-2018 |

27 Apr 2018 |

30 Apr 2023 |

Valid |

Kowloon Bay |

|

|

Construction Noise Permit |

|||||

|

GW-RE0736-22 |

1 Aug 2022 |

30 Jan 2023 |

Superseded by EP/MD/23-088 |

General Works at Ma Tau Kok |

|

|

GW-RE0032-23 |

31 Jan 2023 |

30 Mar 2023 |

Valid |

|

|

|

GW-RE1237-22 |

28 Nov 2022 |

19 May 2023 |

Valid |

General Works at Kai Tak |

|

|

GW-RE1335-22 |

21 Dec 2022 |

20 Jun 2023 |

Valid |

General Works at Stage 1 Underwater Tunnel |

|

|

GW-RE1101-22 |

17 Oct 2022 |

16 Apr 2023 |

Valid |

General Works at Stage 2 Underwater Tunnel |

|

|

GW-RE0766-22 |

3 Aug 2022 |

2 Feb 2023 |

Valid |

General Works at KT Barging Facility (KTW) |

|

|

Chemical

Waste Producer Registration |

|||||

|

5118-247-G2347-47 |

30 Jan 2018 |

End of Project |

Valid |

-- |

|

|

5118-247-G2347-48 |

30 Jan 2018 |

End of Project |

Valid |

-- |

|

|

Marine Dumping Permit |

|||||

|

EP/MD/23-046 |

21-Nov-2022 |

28-Feb-2023 |

Valid |

Sediments

requiring Type 1 - Open Sea Disposal |

|

|

EP/MD/23-072 |

12 Dec 2022 |

11 Jan 2023 |

Superseded by EP/MD/23-088 |

Sediments requiring

Type 1 (Dedicated Site) and Type 2 Confined Marine Disposal |

|

|

EP/MD/23-088 |

12 Jan 2023 |

11 Feb 2023 |

Valid |

|

|

|

Billing Account for Construction

Waste Disposal |

|||||

|

7029909 |

22 Jan 2018 |

End of Project |

Account Active |

-- |

|

|

7031949 |

29 Nov2022 |

28 Feb 2023 |

Account Active |

Billing Account for Disposal of Construction Waste (by

vessels) |

|

|

Notification Under Air Pollution

Control (Construction Dust) Regulation |

|||||

|

429442 |

5 Jan 2018 |

5 Jul 2025 |

Notified |

-- |

|

|

|

|||||

3

Environmental Monitoring Requirements

3.1 Construction Dust Monitoring

Monitoring Requirements

3.1.1

In accordance

with the approved EM&A Manual, measurement of 24-hour and 1-hour Total

Suspended Particulates (TSP) level at the designated air quality monitoring

station is required. Impact 24-hour TSP monitoring should be carried out for at

least once every 6 days, and 1-hour TSP monitoring should be done at least 3

times every 6 days while the highest dust impact is expected. The Action and

Limit Levels of the air quality monitoring is provided in Appendix

D.

Monitoring Equipment

3.1.2

24-hour TSP air

quality monitoring was performed using High Volume Sampler (HVS) located at the

designated monitoring station. The HVS meets all the requirements of the

EM&A Manual.

3.1.3

A portable direct

reading dust meter was used to carry out the 1-hour TSP monitoring.

3.1.4

Brand and model

of the equipment is given in Table

3.1.

Table 3.1 Air Quality Monitoring Equipment

|

Tisch

Total Suspended Particulate Mass Flow Controlled High Volume Air Sampler |

|

|

Calibration

Kit (24-hour

TSP) |

TISCH

Environmental Orifice |

|

Portable

direct reading dust meter |

Sibata Digital Dust Monitor |

Monitoring Locations

3.1.5

The monitoring

station for construction dust monitoring pertinent to the Project has been

identified based on the approved EM&A Manual for the Project. The location of the construction dust

monitoring station is summarized in Table

3.2 and shown in Figure 3.1.

Table 3.2 Location of Construction Dust Monitoring Station

|

Location |

Monitoring Station |

Description |

|

E-A14a

[1] |

Block

B of Merit Industrial Centre |

Rooftop

(13/F) |

[1] The air monitoring station

proposed in the EM&A Manual (i.e. Wyler Gardens with ID: E-A14) was not

available for impact dust monitoring, therefore impact monitoring was conducted

at E-A14a as an alternative which was agreed by the ER, IEC and EPD.

Monitoring

Methodology

3.1.6

24-hour TSP

Monitoring

(a)

The HVS

was installed in the vicinity of the air sensitive receivers. The following criteria were considered in the

installation of the HVS as far as practicable: -

(i)

A horizontal platform with

appropriate support to secure the sampler against gusty wind was provided.

(ii)

Two samplers should

not be placed less than 2m apart from each other;

(iii)

The distance between the HVS and

any obstacles, such as buildings, was at least twice the height that the

obstacle protrudes above the HVS.

(iv)

A minimum of 2 meters separation

from walls, parapets and penthouse for rooftop sampler.

(v)

A minimum of 2 meters separation

from any supporting structure, measured horizontally is required.

(vi)

No furnace or incinerator flues

nearby.

(vii)

Airflow around the sampler was

unrestricted.

(viii)

The sampler was located more than

20 meters from any dripline.

(ix)

Any wire fence and gate, required

to protect the sampler, did not obstruct the monitoring process.

(x)

Permission was obtained to set up

the samplers and access to the monitoring station.

(xi)

A secured supply of electricity

was obtained to operate the sampler.

(b)

Preparation

of Filter Papers

(i)

Glass fibre filters, G810 were

labelled and sufficient filters that were clean and without pinholes were

selected.

(ii)

All filters were equilibrated in

the conditioning environment for 24 hours before weighing. The conditioning

environment temperature was around 25 °C and not variable by more than ±3 °C;

the relative humidity (RH) was < 50% and not variable by more than ±5%. A

convenient working RH was 40%.

(iii)

All filter papers were prepared

and analysed by ALS Technichem (HK) Pty Ltd., which is a HOKLAS accredited

laboratory and has comprehensive quality assurance and

quality control programmes.

(c)

Field

Monitoring

(i)

The power

supply was checked to ensure the HVS works properly.

(ii)

The filter holder and the area

surrounding the filter were cleaned.

(iii)

The filter holder was removed by

loosening the four bolts and a new filter, with stamped number upward, on a

supporting screen was aligned carefully.

(iv)

The filter was properly aligned

on the screen so that the gasket formed an airtight seal on the outer edges of

the filter.

(v)

The swing bolts were fastened to

hold the filter holder down to the frame.

The pressure applied was sufficient to avoid air leakage at the edges.

(vi)

Then the shelter lid was closed

and was secured with the aluminium strip.

(vii)

The HVS was warmed-up for about 5

minutes to establish run-temperature conditions.

(viii)

A new flow rate record sheet was

set into the flow recorder.

(ix)

On site temperature and

atmospheric pressure readings were taken and the flow rate of the HVS was

checked and adjusted at around 1.3 m3/min, and complied with the

range specified in the EM&A Manual (i.e. 0.6-1.7 m3/min).

(x)

The programmable digital timer

was set for a sampling period of 24 hrs, and the starting time, weather

condition and the filter number were recorded.

(xi)

The initial elapsed time was

recorded.

(xii)

At the end of sampling, on site

temperature and atmospheric pressure readings were taken and the final flow

rate of the HVS was checked and recorded.

(xiii)

The final elapsed time was

recorded.

(xiv)

The sampled filter was removed

carefully and folded in half length so that only

surfaces with collected particulate matter were in contact.

(xv)

It was then placed in a clean

envelope and sealed.

(xvi)

All monitoring information was

recorded on a standard data sheet.

(xvii)

Filters were then sent to ALS Technichem (HK)

Pty Ltd. for analysis.

(d)

Maintenance

and Calibration

(i)

The HVS and its accessories were maintained in good working condition, such as

replacing motor brushes routinely and checking electrical wiring to ensure a

continuous power supply.

(ii)

HVSs were calibrated using

TE-5025A Calibration Kit upon installation and thereafter at bi-monthly

intervals.

(iii)

Calibration certificate of the TE-5025A Calibration Kit and the HVSs are provided in

Appendix E.

3.1.7

1-hour TSP

Monitoring

(a)

Measuring Procedures

The measuring procedures of the 1-hour dust meter are in accordance with

the Manufacturer’s Instruction Manual as follows:

(i)

Turn the power on.

(ii)

Close the air collecting opening cover.

(iii)

Push the “TIME SETTING” switch to [BG]

(iv)

Push “START/STOP”

switch to perform background measurement for 6 seconds.

(v)

Turn the knob at SENSI ADJ position to insert

the light scattering plate.

(vi)

Leave the equipment for 1 minute upon “SPAN

CHECK” is indicated in the display.

(vii)

Push “START/STOP” switch to perform automatic

sensitivity adjustment. This measurement takes 1 minute.

(viii)

Pull out the knob and return it to MEASURE

position.

(ix)

Push the “TIME SETTING” switch the time set

in the display to 3 hours.

(x)

Lower down the air collection opening cover.

(xi)

Push “START/STOP” switch to start

measurement.

(b)

Maintenance and

Calibration

(i)

The 1-hour TSP meter

was calibrated at 1-year intervals against a High Volume Samplers. Calibration certificates of the Laser Dust Monitors are provided in Appendix E.

Monitoring Schedule for the

Reporting Month

3.1.8

The schedule for

environmental monitoring in January 2023 is provided in Appendix

F.

3.2 Construction Noise Monitoring

Monitoring Requirements

3.2.1

In accordance

with the EM&A Manual, impact noise monitoring should be conducted for at

least once a week during the construction phase of the Project. Table

3.3 summarizes the monitoring parameters, frequency

and duration of impact noise monitoring. The Action and Limit Levels of the

noise monitoring is provided in Appendix D.

Table 3.3 Noise Monitoring Parameters, Frequency and Duration

|

Parameter and Duration |

Frequency |

|

30-mins

measurement at each monitoring station between 0700 and 1900 on normal

weekdays. Leq, L10 and L90

would be recorded. |

At least once per week |

3.2.2

Noise monitoring

was performed using sound level meter at each designated monitoring

station. The sound level meters deployed

comply with the International Electrotechnical Commission Publications (IEC)

651:1979 (Type 1) and 804:1985 (Type 1) specifications. Acoustic calibrator was deployed to check the

sound level meters at a known sound pressure level. Brand and model of the equipment is given in Table

3.4.

Table 3.4 Noise Monitoring Equipment for Regular Noise Monitoring

|

B&K (Model No. 2250, 2250L& 2270) |

|

|

Acoustic

Calibrator |

Rion (Model No.

NC-74) & B&K (Model No. 4231) |

Monitoring Locations

3.2.3

The monitoring

stations for construction noise monitoring pertinent to the Project have been

identified based on the approved EM&A Manual for the Project. Locations of the noise monitoring stations are

summarized in Table

3.5 and shown in Figure

3.2.

Table 3.5 Noise Monitoring Stations during Construction Phase

|

Location |

Monitoring Station |

Description |

Measurement |

|

E-N12a [1] |

19 Hing Yan Street |

Rooftop (9/F) |

Façade |

|

E-N21a [1] |

Block B of Merit Industrial Centre |

Rooftop (13/F) |

Free field[2] |

Notes:

[1] The noise monitoring stations proposed in the

EM&A Manual (i.e. Grand Waterfront Tower 3 with ID: E-N12 and Hang Chien Court Block J with ID: E-N21) were not available for

impact noise monitoring, therefore impact monitoring was conducted at E-N12a

and E-N21a as an alternative which was

agreed by the ER, IEC and EPD.

[2] A

correction of +3 dB(A) was made to the free field measurements.

Monitoring Parameters, Frequency and Duration

3.2.4

Table 3.6 summarizes the monitoring parameters,

frequency and duration of impact noise monitoring.

Table 3.6 Noise Monitoring Parameters, Frequency and Duration

|

Location |

Parameter and Duration |

Frequency |

|

E-N12a

and E-N21a |

30-mins measurement at each

monitoring station between 0700 and 1900 on normal weekdays. Leq, L10 and L90 would

be recorded. |

At

least once per week |

Monitoring Methodology

3.2.5

Monitoring

Procedure

(a)

The sound level meter was set on

a tripod at a height of 1.2 m above the ground.

(b)

Façade measurement was made at E-N12a.

(c)

Free field measurements was made

at monitoring location E-N21a. A correction of +3 dB(A) shall be made to the

free field measurements.

(d)

The battery condition was checked to ensure the correct

functioning of the meter.

(e)

Parameters such as frequency

weighting, the time weighting and the measurement time were set as follows:

(i)

frequency weighting

(ii)

time weighting: Fast

(iii)

time measurement: Leq(30-minutes) during non-restricted

hours i.e. 0700 – 1900 on normal weekdays.

(f)

Prior to and after each noise

measurement, the meter was calibrated using the acoustic calibrator for 94

dB(A) at 1000 Hz. If the difference in

the calibration level before and after measurement was more than 1 dB(A), the

measurement would be considered invalid and repeat of noise measurement would

be required after re-calibration or repair of the equipment.

(g)

During the monitoring period, the

Leq, L10 and L90

were recorded. In addition, site

conditions and noise sources were recorded on a standard record sheet.

(h)

Noise measurement was paused

during periods of high intrusive noise (e.g. dog barking, helicopter noise) if

possible. Observations were recorded when intrusive noise was unavoidable.

(i)

Noise monitoring was cancelled in

the presence of fog, rain, wind with a steady speed exceeding 5m/s, or wind

with gusts exceeding 10m/s.

3.2.6

Maintenance and

Calibration

(a)

The

microphone head of the sound level meter was cleaned with soft

cloth at regular intervals.

(b)

The meter

and calibrator were sent to the supplier or HOKLAS laboratory to check and

calibrate at yearly intervals.

(c)

Calibration

certificates of the sound level meters and acoustic calibrators are

provided in Appendix E.

Monitoring

Schedule for the Reporting Month

3.2.7 The schedule for

environmental monitoring in January 2023 is provided in Appendix F.

3.3

Landscape and Visual

3.3.1 As per the EM&A Manuals, the landscape and visual mitigation

measures shall be implemented and site inspections should be undertaken once

every two weeks during the construction period. A summary of the implementation

status is presented

in Section 6.

4

Implementation Status of Environmental Mitigation Measures

4.1.1

The

Contractor has implemented environmental mitigation measures and requirements

as stated in the EIA Reports, the EP and EM&A Manuals. The implementation

status of the environmental mitigation measures during the reporting period is

summarized in Appendix C. Status of required submissions under the EP

during the reporting period is summarised in Table 4.1.

Table 4.1 Status of Required Submission under Environmental Permit

|

EP Condition |

Submission |

Submission

Date |

|

Condition 3.4 of |

Monthly EM&A Report

for December 2022 |

14 January 2023 |

5

Monitoring Results

5.1 Construction Dust Monitoring

5.1.1 The monitoring results for 24-hour TSP and 1-hour TSP are summarized in Table 5.1 and Table 5.2 respectively. Detailed air quality monitoring results and daily extract of meteorological observations are presented in Appendix G.

Table 5.1 Summary of 24-hour

TSP Monitoring Result in the Reporting Period

|

ID |

Average (mg/m3) |

Range (mg/m3) |

Action Level (mg/m3) |

Limit Level (mg/m3) |

|

E-A14a |

44.4 |

18.4 – 63.6 |

197.3 |

260 |

Table 5.2 Summary of 1-hour TSP Monitoring Result in the Reporting Period

|

ID |

Average (mg/m3) |

Range (mg/m3) |

Action Level (mg/m3) |

Limit Level (mg/m3) |

|

E-A14a |

60.2 |

57.4

– 63.4 |

302.4 |

500 |

5.1.2

No Action and Limit Level exceedance was recorded

for 24-hour TSP monitoring at the monitoring

location in the reporting month.

5.1.3 No Action and

Limit Level exceedance was recorded for 1-hour TSP monitoring at the monitoring location in the reporting month.

5.1.4 The event and action

plan are annexed in Appendix I.

5.1.5

Major dust

sources during the monitoring included construction dust and nearby traffic

emission.

5.2 Regular Construction Noise Monitoring

5.2.1

The

monitoring results for noise are summarized in Table 5.3 and the monitoring data is provided in Appendix

H.

Table 5.3 Summary of Construction Noise Monitoring Results in the Reporting Period

|

ID |

Range, dB(A), Leq (30 mins) |

Limit Level, dB(A), Leq (30 mins) |

|

E-N12a |

66.1

– 68.5 |

75 |

|

E-N21a |

60.3

– 65.1 |

75 |

5.2.2 One (1) action level

exceedance was recorded regarding to complaint on noise nuisance received in

the reporting month. No limit level exceedance was recorded at all monitoring

stations in the reporting month.

5.2.3 The event and action

plan are annexed in Appendix I.

5.2.4 Major noise sources during the monitoring included construction noise from the Project site and nearby traffic noise.

5.3 Waste Management

5.3.1 C&D materials and wastes sorting were carried

out on site. Receptacles were available for C&D wastes and general refuse collection.

5.3.2 As advised by the Contractor, total 7,733 m3 of inert

C&D material were generated

and 7,733 m3 of C&D material was

disposed to public fill, no inert C&D was reused in the Contract and no other projects

respectively in the reporting month.84,540 kg

of general refuse was generated and

sent to NENT Landfill in

the reporting month. No metal, plastics and paper/cardboard

packaging were collected by recycle contractor in the reporting month. No chemical

waste was collected by licensed contractor in the reporting month. 8,633 m3 of Type 1, 5,057 m3

of Type 2 and

no Type 3 Marine sediment were disposed at Confined Marine Disposal Facility to

the East of Sha Chau. The waste flow table is annexed in Appendix K.

5.3.3

The Contractor

is advised to properly maintain on site C&D materials and wastes

collection, sorting and recording system and maximize reuse / recycle of

C&D materials and wastes. The Contractor is reminded to properly maintain

the site tidiness and dispose of the wastes accumulated on site regularly and

properly.

5.3.4

The Contractor

is reminded that chemical waste containers should be properly treated and

stored temporarily in designated chemical waste storage area on site in

accordance with the Code of Practice on the Packaging, Labelling and Storage of

Chemical Wastes.

5.4

Landscape and Visual

5.4.1 Bi-weekly inspection of the

implementation of landscape and visual mitigation measures was conducted on 11 and

26 January 2023. A summary of the site inspection is provided in Appendix C. The observations and

recommendations made during the site inspections are presented in Table 6.1.

6

ENVIRONMENTAL SITE INSPECTION AND AUDIT

6.1.1

Site inspections were carried out on a weekly basis to

monitor the implementation of proper environmental pollution control and

mitigation measures for the Project. A summary of the mitigation measures

implementation schedule is provided in Appendix C.

6.1.2 In the reporting month, 4 site

inspections were carried out on 4, 11, 18 and 26 January 2023. Joint inspections with the IEC, ER, the Contractor and ET were

conducted on 18 January 2023. No non-compliance was recorded during the site

inspection. Details of observations recorded during the site inspections are

presented in Table 6.1.

Table 6.1 Observations and Recommendations of Site Audit

|

Parameters |

Date |

Observations and Recommendations |

Follow-up |

|

Air Quality |

Nil |

Nil |

Nil |

|

Noise |

18

Jan 2023 |

Observation ·

The excavator at MTK was

observed missing covering the acoustic sheet. The Contractor was advised to

ensure the acoustic sheet should be covering to all PMEs to reduce noise. |

The item was rectified by the Contractor on |

|

Water Quality |

4

Jan 2023 |

Observation · The oil/ grease was observed floating on the sea at the

intorier of the silt curtain at marine plaform stage 2. The contractor was

advised to ensure remove the oil/ grease and keep clean to prevent marine

pollution. |

The item was rectified by the Contractor on |

|

18

Jan 2023 |

Observation The bad condition of the tarpaulin sheet was observed using in the soil

dumping operation.The Contractor was advised to ensure using good condition

tarpauline sheet to prevent accidential soil dropping into the sea and cause

marine pollution. |

The item was rectified by the Contractor on |

|

|

Waste/ Chemical Management |

4

Jan 2023 |

Observation ·

The chemical containers

were observed locating on the ground without drip tray at MTK. The contractor

was advised to ensure the chemical containers should be placing in the drip

tray. |

The item was rectified by the Contractor on |

|

11

Jan 2023 |

Observation ·

The chemical containers

were observed locating on the ground without drip tray at Underpass Tunnel

and Stockpile Area. The Contractor was advised to ensure the chemical

containers should be placing in the drip tray. |

The item was rectified by the Contractor on |

|

|

Landscape & Visual |

Nil |

Nil |

Nil |

|

Permits/ Licenses |

Nil |

Nil |

Nil |

6.1.3 All follow-up actions requested by

Contractor's ET during the site inspection were undertaken as reported by the

Contractor and confirmed in the following weekly site inspection conducted during the reporting

period.

7 Environmental Non-conformance

7.1 Summary of Monitoring Exceedances

7.1.1 All 24-hour TSP result

was below the Action and Limit Levels at all monitoring locations in the

reporting month.

7.1.2 All 1-hour TSP result

was below the Action and Limit Levels at all monitoring locations in the

reporting month

7.1.3 One (1) action level exceedance

was recorded regarding to complaints on noise nuisance received in the

reporting month. No limit level exceedance was recorded at all monitoring

stations in the reporting month.

7.2 Summary of Environmental Non-Compliance

7.2.1 No environmental

non-compliance was recorded in the reporting month.

7.3 Summary of Environmental Complaints

7.3.1 Five (5) complaints were

received in the reporting month (January 2023) and the investigation were provided in

the current reporting month (January 2023). Cumulative statistics on environmental complaint is

provided in Appendix J.

7.4 Summary of Environmental Summon and Successful Prosecutions

7.4.1

No

environmental related prosecution or notification of summons was received in

the reporting month. Cumulative statistics on notification of summons and

successful prosecutions is provided in Appendix J.

8

FUTURE KEY ISSUES

8.1 Construction Programme for the Next Three Months

8.1.1 The major construction

works between February 2023 to April 2023 are provided in Table 8.1.

Table 8.1 Construction Activities in the coming three months

|

Locations |

Site Activities |

|

Kai

Tak |

-

Road Pavement at underpass, depressed road and C&C; -

Stitch joint construction at underpass, depressed road and C&C Tunnel; -

Tunnel wall and walkway construction at At-grade road. |

|

Ma

Tau Kok |

-

TTM implementation; - Excavation

at MTK C&C Tunnel; -

Decking and ELS installation at MTK C&C Tunnel; |

|

Kowloon

Bay |

-

Road pavement at Stage 1 UWT; -

Modular strutting installation at Stage 2 UWT -

Excavation at Stage 2 UWT. |